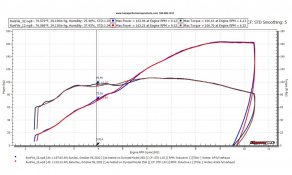

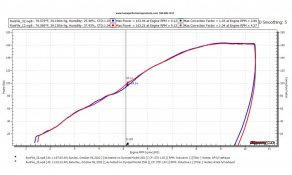

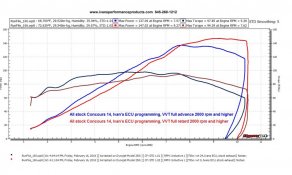

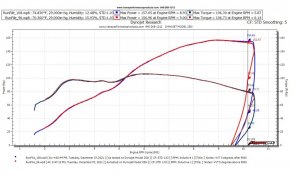

Got thinking about something and thought cam timing is essential to this engine's peak performance since variable timing gives performance levels in the best of both worlds.

especially when tuning past stock parameters you can compensate to build a power level that is broad at all RPMs.

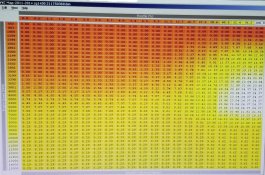

Thinking there are 24 degrees total to work with, and in the cruise throttle position ( The valve timing is ECU controlled by throttle postion ??) so at cruise, it is around 1-6 degrees.

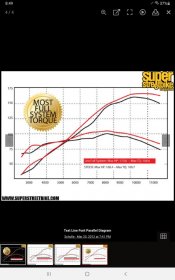

Would think oil type, running-oil quality, and oil pressure play into it for peak performance by not reaching its full articulation, not starting a thread on what brand of oil you have been using ( don't care ) one other thing does exhaust type * (header) and muffler effect and play into cam timing for all-around performance.

especially when tuning past stock parameters you can compensate to build a power level that is broad at all RPMs.

Thinking there are 24 degrees total to work with, and in the cruise throttle position ( The valve timing is ECU controlled by throttle postion ??) so at cruise, it is around 1-6 degrees.

Would think oil type, running-oil quality, and oil pressure play into it for peak performance by not reaching its full articulation, not starting a thread on what brand of oil you have been using ( don't care ) one other thing does exhaust type * (header) and muffler effect and play into cam timing for all-around performance.