-

WOULD YOU LIKE TO BE ABLE TO POST? REGISTER FOR COG MEMBERSHIP

All registration must be done through the club's main webpage: To register / join COG, click here

For instructions to convert to full membership, click here

-

Can't post after logging to the forum for the first time... Try Again - If you can't post in the forum, sign out of both the membership site and the forum and log in again. Make sure your COG membership is active and your browser allow cookies. If you still can't post, contact the COG IT guy at IT@Concours.org.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

90 degree valve stems

- Thread starter ron203

- Start date

I tried a 90 degree valve stem on a rear tire - can't remember where I purchased it and being for a C-10 it had no TPS doodadery. Mine caused a fairly quick loss of air pressure of the rear tire (not the one that caused injuries in 2020). Upon examination of the valve stem it appeared that centrifugal force of the spinning tire may have caused the valve stem to crack near the 90 degree bend. This stem was all rubber - I'm sure steel would withstand that force better. This is all conjecture on my part, The stem may have failed for other reasons.

I got home on the leaky stem by using electrical tape to lift the stem away from the rim - the opposite direction that centrifugal force had applied to the spinning tire. In any event, I went back to conventional valve stems after that.

I got home on the leaky stem by using electrical tape to lift the stem away from the rim - the opposite direction that centrifugal force had applied to the spinning tire. In any event, I went back to conventional valve stems after that.

I tried a 90 degree valve stem on a rear tire - can't remember where I purchased it and being for a C-10 it had no TPS doodadery. Mine caused a fairly quick loss of air pressure of the rear tire (not the one that caused injuries in 2020). Upon examination of the valve stem it appeared that centrifugal force of the spinning tire may have caused the valve stem to crack near the 90 degree bend. This stem was all rubber - I'm sure steel would withstand that force better. This is all conjecture on my part, The stem may have failed for other reasons.

I got home on the leaky stem by using electrical tape to lift the stem away from the rim - the opposite direction that centrifugal force had applied to the spinning tire. In any event, I went back to conventional valve stems after that.

I carry a 90 degree screw-on extension in my tire kit in case I can’t fit a gas station chuck on the regular one, but I don’t leave it on all the time. When I’m done, it comes back off and into the tire kit. Apparently Murph’s Kits have some that integrate into the tpms unit and it’s permanent like the ones on my Goldwing. That’s what I’m looking for info on. Thanks

Wheel valve stem question

I've been toying with replacing the factory straight valve stems. I see that the 1st generation had TPMS hardware on them. Will regular 90 degree valve stems fit my '22? Puig sells some real nice green ones.

I installed at my last tire change. It is a super easy process by just using the appropriate Allen head socket to remove the TPMS sensor from the stem. I put a tiny amount of silicone grease on the new O-ring of the 90 degree stem to allow it to seat best. The maintenance manual has a torque specification for installing. I love the new stems as I am not fighting with a brake rotor to check and fill my tires.Who has actually installed these (from Murph’s Kits or ?) on a C-14? How hard was it?

@Jorge and @ rlievenski4555

That’s the sort of answers I was fishing for.

I’ve struggled with the straight stems from the beginning on my 2014 and finally bought a swivel head chuck for my home compressor which helped a bit. Cliff’s temporary angle extension approach helps too, but the permanent 90’s like on my Goldwing seem to be the solution.

We’ve got a casual group of COGers who write about stuff for the Concourier and it occurs to me that this might be the basis for a short useful piece for the magazine. Anybody interested? Please think about it and let me know. Easy peasy.

Even if you had it done at a tire change, it’s still a useful piece of information.

Sometimes the little things are nice to do, too! Are there any options for the 2015+ models? Maybe those Puig stems that were mentioned? I’m not familiar with them.

Thanks guys!

Ron

That’s the sort of answers I was fishing for.

I’ve struggled with the straight stems from the beginning on my 2014 and finally bought a swivel head chuck for my home compressor which helped a bit. Cliff’s temporary angle extension approach helps too, but the permanent 90’s like on my Goldwing seem to be the solution.

We’ve got a casual group of COGers who write about stuff for the Concourier and it occurs to me that this might be the basis for a short useful piece for the magazine. Anybody interested? Please think about it and let me know. Easy peasy.

Even if you had it done at a tire change, it’s still a useful piece of information.

Sometimes the little things are nice to do, too! Are there any options for the 2015+ models? Maybe those Puig stems that were mentioned? I’m not familiar with them.

Thanks guys!

Ron

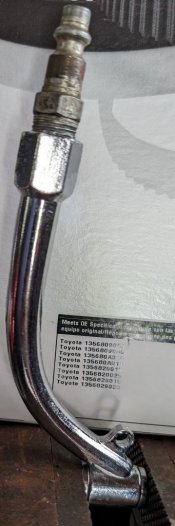

Did you heat that and reshape it?Ron, this is the answer for filling tires with straight calve stems. They clear the rotors and give you good leverage to be able to press on the valve properly.

I have a new little project. Thanks Jorge.Custom work by a local shop named Silva Vise & Hammer works.

No heating needed Bud.

I bent it a little at a time, moving it out on the vise as I bent each little bend. Probably 6 little bends, then put heat-shrink tubink to cover the dings and give better grip.

I got an air chuck made of brass, it did not bend good, got too close to the end and it snapped, was only out $4. Got another and filled it with sand hoping to stop the kinks, snapped again at the threads, I went too far to the end, but it would have worked perfect. I was using a metal pipe that slipped over the shaft while I had it in a vise. Maybe the chromed metal one will bend better?

You know, here's the thing. I really don't have a problem filling it at home, I have a 90 degree air chuck and I just reach in and under and over and it works just fine. The problem is when I'm not at home, it is virtually impossible to fill your tires anywhere as everyone uses the long shaft air chuck at filling stations. I don't really want to drag out the portable air compressor I use for a flat tire just to put 2 lbs. in my front tire. That's why we need 90 degree or at least 45 degree valves. I used a pair I got long ago from Murph on the C-10, he only sells pre '15 90 degree valves now. That's why if asked if the aftermarket valves I see from Puig and Cycle Gear will work with our TPMS systems.

So, again, I will ask, is anybody using non-factory 45 or 90 degree valves stems on their post 2015 C-14? If so, what brand?

You know, here's the thing. I really don't have a problem filling it at home, I have a 90 degree air chuck and I just reach in and under and over and it works just fine. The problem is when I'm not at home, it is virtually impossible to fill your tires anywhere as everyone uses the long shaft air chuck at filling stations. I don't really want to drag out the portable air compressor I use for a flat tire just to put 2 lbs. in my front tire. That's why we need 90 degree or at least 45 degree valves. I used a pair I got long ago from Murph on the C-10, he only sells pre '15 90 degree valves now. That's why if asked if the aftermarket valves I see from Puig and Cycle Gear will work with our TPMS systems.

So, again, I will ask, is anybody using non-factory 45 or 90 degree valves stems on their post 2015 C-14? If so, what brand?

Tom, you plannimg on rebuilding a Chevy small block?

Actually, one of the CMA chapter members in Orange Park FL haf about 3x thst many tools.

@Strawboss, I bought the ones Murph sells, installed one so far. It was easy, fast, and works great.

Actually, one of the CMA chapter members in Orange Park FL haf about 3x thst many tools.

@Strawboss, I bought the ones Murph sells, installed one so far. It was easy, fast, and works great.

For the small number of bikes made by a maker like Kawasaki, and of all the "input" they ask of new buyers on how they can improve or what you'd like to see on a new bike, why can't they spend an extra few dollars and spread that cost to the rest of the bikes to install something so very simple and yet so very practical as 45 or 90 degree valve stems? I guess it's like bars,pegs, and seats as those are the first to be replaced, but stems cost so much less.

As I was using brass and it was more bendable and therefore less forgiving, I bent it less and got a swivel head for the male air chuck, you can see where I got too aggressive and it broke. This works perfect, I stick it through a hole in the rotor, and it lines up great.

As I was using brass and it was more bendable and therefore less forgiving, I bent it less and got a swivel head for the male air chuck, you can see where I got too aggressive and it broke. This works perfect, I stick it through a hole in the rotor, and it lines up great.

Ha.Tom, you plannimg on rebuilding a Chevy small block?

Actually, one of the CMA chapter members in Orange Park FL haf about 3x thst many tools.

@Strawboss, I bought the ones Murph sells, installed one so far. It was easy, fast, and works great.

When we are out somewhere and you need sumthin.....just remember. Been working on finding smaller multiple use stuff. I put this one together from the ADV thread. https://www.advrider.com/f/threads/the-toolkit-thread.262998/

I must've been fortunate...I actually bent three and none broke. Probably because I bought the cheap steel ones??As I was using brass and it was more bendable and therefore less forgiving, I bent it less and got a swivel head for the male air chuck, you can see where I got too aggressive and it broke. This works perfect, I stick it through a hole in the rotor, and it lines up great.View attachment 38306

Nope. I actually scrounged up some patience and a propane torch. Gotta be careful because once it gets hot enough, it'll bend quickly. It took three attempts to get it done. I had already failed with a brass tube model and didn't want a repeat failure. I discovered that the one with the brass tube threaded in to the chuck.Wow...nice work!

You must have a tube bender.

I had the same result with 90 degree rubber valve stems. I was stranded on the highway for nearly two hours waiting for a wrecker, all because I could air up the tire at the gas station. My fix now in standard valve stems and the portable Airmoto air pump. It has a flexible tube. If all you are doing is adding a few pounds of air, the battery operated Airmoto pump is the Bomb digity. Love mine. I won't leave home without it.I tried a 90 degree valve stem on a rear tire - can't remember where I purchased it and being for a C-10 it had no TPS doodadery. Mine caused a fairly quick loss of air pressure of the rear tire (not the one that caused injuries in 2020). Upon examination of the valve stem it appeared that centrifugal force of the spinning tire may have caused the valve stem to crack near the 90 degree bend. This stem was all rubber - I'm sure steel would withstand that force better. This is all conjecture on my part, The stem may have failed for other reasons.

I got home on the leaky stem by using electrical tape to lift the stem away from the rim - the opposite direction that centrifugal force had applied to the spinning tire. In any event, I went back to conventional valve stems after that.

For my roadside tire kit, I have one of these with the 90-degree chuck, and it fits onto the 1" straight valve stems on my C10 quite easily. It has an SAE plug that I connect to my battery tender lead. The only minor annoyance is that it doesn't have an integrated gauge, so I have to pop it off and check pressure separately. But otherwise, it's a really well-built and compact pump. The plug kit they sell is also really compact, and packs down inside the hollow tool handle.

I keep both the pump and plug kit in the padded bag the pump comes with, tucked into the space between the battery case and rear fender. It fits perfectly there.

www.motopumps.com

www.motopumps.com

I keep both the pump and plug kit in the padded bag the pump comes with, tucked into the space between the battery case and rear fender. It fits perfectly there.

MotoPumps® Air Shot 2.1 - Made in the USA ! — MotoPumps - Performance Under Pressure!

$79.99-$89.99 MSRP The MotoPumps® Air Shot 2.1 is our newest model. Designed, Engineered and Built right here in the USA. Our carry cases are very high quality and designed to pack easily and protect your MotoPump. They are 600 denier nylon with a 1/4 inch tricot foam padding bonded inside. Custo

I bought a Lexin inflator some weeks ago. Last week I tested it on my rear tire (in the garage, I let all the air out).

I set ut to 42 PSI, and turned it on.

I'll do a more complete review later, but in just over 10 minutes my rear, 190/55R17 was at 42 PSI, and a few seconds later it shut off. Very pleased.

I set ut to 42 PSI, and turned it on.

I'll do a more complete review later, but in just over 10 minutes my rear, 190/55R17 was at 42 PSI, and a few seconds later it shut off. Very pleased.

I bought a Lexin inflator some weeks ago. Last week I tested it on my rear tire (in the garage, I let all the air out).

I set ut to 42 PSI, and turned it on.

I'll do a more complete review later, but in just over 10 minutes my rear, 190/55R17 was at 42 PSI, and a few seconds later it shut off. Very pleased.

Link? Several choices on Amazon. Thx

I carry a Slime mini compressor and tire plug kit from Walmart. It plugs into the heated gear pigtail and has rescued me twice. It does suck on the battery though and last time I had to idle the bike for the last 3-5 minutes.But I like the idea of the wireless compressor.

I have had these installed on my 12' for about 10 years without any issues. If you're already taking the wheel and tire off yourself, you should not find installation a problem.