-

WOULD YOU LIKE TO BE ABLE TO POST? REGISTER FOR COG MEMBERSHIP

All registration must be done through the club's main webpage: To register / join COG, click here

For instructions to convert to full membership, click here

-

Can't post after logging to the forum for the first time... Try Again - If you can't post in the forum, sign out of both the membership site and the forum and log in again. Make sure your COG membership is active and your browser allow cookies. If you still can't post, contact the COG IT guy at IT@Concours.org.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

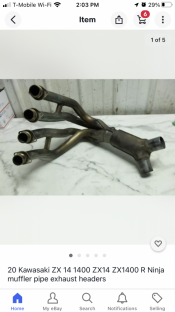

ZX-14 or ZX-14R Exhaust for a C-14?

- Thread starter connie_rider

- Start date

Thanks for posting those Ron.

How to build or install something on a Connie I can {eventually} figure out.

How to post photo's here,,, no way..

I are computer illiterate and proud of it.

Ride safe, Ted

PS: Just installed the Piaa horn's…

LOUD!!!!

How to build or install something on a Connie I can {eventually} figure out.

How to post photo's here,,, no way..

I are computer illiterate and proud of it.

Ride safe, Ted

PS: Just installed the Piaa horn's…

LOUD!!!!

Had a setback on my Muzzy install. :truce:

Grandson and I took the bike out for a good test and we drug {dragged?} the mid-pipes on both sides.

And we didn't even get into some real twisties!!

NOTE: I had extended the mid-pipes out about 3' to improve how the Muzzy's fit my headers.

My bike is lowered. {But I never drug the Area P system I had on the bike previously}. (this included some track days)

Soooo, Last night, I removed the 3" extension's and moved the front of the mid- pipes in..

Will give it another try soon. Probably at the National in Kerrville.... :great:

If this doesn't work, I'm considering raising the bike, or another set of mufflers. :-[

Ride safe, Ted

Grandson and I took the bike out for a good test and we drug {dragged?} the mid-pipes on both sides.

And we didn't even get into some real twisties!!

NOTE: I had extended the mid-pipes out about 3' to improve how the Muzzy's fit my headers.

My bike is lowered. {But I never drug the Area P system I had on the bike previously}. (this included some track days)

Soooo, Last night, I removed the 3" extension's and moved the front of the mid- pipes in..

Will give it another try soon. Probably at the National in Kerrville.... :great:

If this doesn't work, I'm considering raising the bike, or another set of mufflers. :-[

Ride safe, Ted

Post National Report;

Slightly drug the {bottom/left} mid pipe again. {My (1 1/2") lowered bike is just too low}

Some burble, surging when riding at "very" low throttle openings}.

{Any throttle opening above the initial crack, runs like a scalded dog!!}

To my ear, these puppies are too loud. {others liked the sound}

Suspension preload is set as hard as possible to give me ground clearance. {Rough when riding}

Da Plan:

The Muzzy mid pipes/mufflers will be coming off.

{for now} Plan is to replace the right side Muzzy with an Area P Slip On and plug the left side.

{later} Trying to find a used Area P to install on the left side.

Area P has smaller OD mid pipe and inside of Muffler is smaller.

{Might help ground clearance issues, and maybe the burble, surging?}

Raise the bike about 3/4", and soften the preload on the springs.

{Change drop from 1 1/2" to 3/4". {I think I discovered how to build my own Lowering Link at "any" height I want.}

Pick Steve's brain to see if he has any suggestions on the Flash I'm using. (he told me I would have a problem)

I have his Mountain Runner Flash and it is great with my Stock exhaust and Area P slip on. {HIGHLY recommended}

Wondering; Maybe his Area P {Full System} flash would work better with the ZX header?

Ride safe, Ted

Slightly drug the {bottom/left} mid pipe again. {My (1 1/2") lowered bike is just too low}

Some burble, surging when riding at "very" low throttle openings}.

{Any throttle opening above the initial crack, runs like a scalded dog!!}

To my ear, these puppies are too loud. {others liked the sound}

Suspension preload is set as hard as possible to give me ground clearance. {Rough when riding}

Da Plan:

The Muzzy mid pipes/mufflers will be coming off.

{for now} Plan is to replace the right side Muzzy with an Area P Slip On and plug the left side.

{later} Trying to find a used Area P to install on the left side.

Area P has smaller OD mid pipe and inside of Muffler is smaller.

{Might help ground clearance issues, and maybe the burble, surging?}

Raise the bike about 3/4", and soften the preload on the springs.

{Change drop from 1 1/2" to 3/4". {I think I discovered how to build my own Lowering Link at "any" height I want.}

Pick Steve's brain to see if he has any suggestions on the Flash I'm using. (he told me I would have a problem)

I have his Mountain Runner Flash and it is great with my Stock exhaust and Area P slip on. {HIGHLY recommended}

Wondering; Maybe his Area P {Full System} flash would work better with the ZX header?

Ride safe, Ted

Removed the right Muzzy Muffler/Mid-pipe and temporarily installed the Area P Muffler/Mid-pipe.

For now, I kept the Muzzy on the left side so (By blocking one or the other) I can hear the difference in sound.

The Area P is not that much quieter, but has a different/deeper tone.

Also gave me more ground clearance.

Tonight, I will finish the Area P install, remove, the left Muzzy, and plug that side for now.

Will see how that runs...

Ride safe, Ted

For now, I kept the Muzzy on the left side so (By blocking one or the other) I can hear the difference in sound.

The Area P is not that much quieter, but has a different/deeper tone.

Also gave me more ground clearance.

Tonight, I will finish the Area P install, remove, the left Muzzy, and plug that side for now.

Will see how that runs...

Ride safe, Ted

Previous Post National Report;

Slightly drug the {bottom/left} mid pipe again. {My (1 1/2") lowered bike is just too low}

Some burble, surging when riding at "very" low throttle openings}.

{Any throttle opening above the initial crack, runs like a scalded dog!!}

To my ear, these puppies are too loud. {others liked the sound}

Latest Ride report with 1 Area P Muffler installed.

No more; burble, surging when riding at "very" low throttle openings.

Runs good!! Smooth roll on/cruise. But may have lost bit of the WOT power.

Did not drag anything. The Area P Mid Pipe has more ground clearance..

As I'm crazy and like to tinker,,,, I currently installing a second Area p Muffler on the left side.

Building my own left Mid Pipe.

Ride safe, Ted

Slightly drug the {bottom/left} mid pipe again. {My (1 1/2") lowered bike is just too low}

Some burble, surging when riding at "very" low throttle openings}.

{Any throttle opening above the initial crack, runs like a scalded dog!!}

To my ear, these puppies are too loud. {others liked the sound}

Latest Ride report with 1 Area P Muffler installed.

No more; burble, surging when riding at "very" low throttle openings.

Runs good!! Smooth roll on/cruise. But may have lost bit of the WOT power.

Did not drag anything. The Area P Mid Pipe has more ground clearance..

As I'm crazy and like to tinker,,,, I currently installing a second Area p Muffler on the left side.

Building my own left Mid Pipe.

Ride safe, Ted

Finally finished the mid pipe and installed the left Area P Muffler on the bike.

Looks good, sounds good, (lots quieter than the Muzzy Mufflers were} will test it soon.

Ride safe, Ted

Looks good, sounds good, (lots quieter than the Muzzy Mufflers were} will test it soon.

Ride safe, Ted

Update to the update...

Rode Arkansas last weekend with the new Muffler set up.

Loved it!!!

Surging/loud/popping that I had with the Muzzy's is gone...

I think the difference is the I.D. of the mid pipes and the muffler ID.

Muzzy's were 2 1/4" ID. The Area P's ID is 2"...

For those that don't want to read back, I have 2008 ZX-14 headers installed w/o catalysts.

Ride safe, Ted

Rode Arkansas last weekend with the new Muffler set up.

Loved it!!!

Surging/loud/popping that I had with the Muzzy's is gone...

I think the difference is the I.D. of the mid pipes and the muffler ID.

Muzzy's were 2 1/4" ID. The Area P's ID is 2"...

For those that don't want to read back, I have 2008 ZX-14 headers installed w/o catalysts.

Ride safe, Ted

Hey Ted

I lowered mine years ago, didn't last long , I felt it screwed up the ride, empty pick up truck rough.

As far noise , the Two Brothers sound sweet, I like hearing every burp, crackle, pop, very entertaining

but I respect others so I use the smallest reducers they sell for these cans, not sure how they can call them

mufflers since it's just a open pipe with small holes , but those reducers change everything, domestication.

No need to change anything but those little reducers :great:

Local bike shop where the owner professionally drag races a ZX14 tells me I'm giving away 3HP :'(

I lowered mine years ago, didn't last long , I felt it screwed up the ride, empty pick up truck rough.

As far noise , the Two Brothers sound sweet, I like hearing every burp, crackle, pop, very entertaining

but I respect others so I use the smallest reducers they sell for these cans, not sure how they can call them

mufflers since it's just a open pipe with small holes , but those reducers change everything, domestication.

No need to change anything but those little reducers :great:

Local bike shop where the owner professionally drag races a ZX14 tells me I'm giving away 3HP :'(

Thank you Ron. {I sent you a note}..

Looking at the pictures I actually like the looks better with the Muzzy's, but the Area P mufflers are a better fit for me (Not as loud) and they are tucked in a lot better. More ground clearance..

Cuda, my Muzzy's don't have the inserts, nor holes to install them. Can you send a photo of yours?

I set the spring sag and mine is now rougher than I like. Would decrease pre-load but right now nothing drags in the twisties. Afraid softening it may make things drag when I'm playing in the Arkansas twisties with Cliff.

Currently building my own lowering links as I'm a bit too low..

Now at 1 1/4" drop. Changing that to 3/4" drop... >

If that works out, I'll soften the preload a bit.

NOTE: I don't like the adjustable links as I prefer to use my center stand..

Talked to Steve. {Geez he's knowledgeable!}

He thinks there's more power available with a bit of tuning.. :great:

Ride safe, Ted

PS: {Please don't tell him I sed something nice about him.}

Looking at the pictures I actually like the looks better with the Muzzy's, but the Area P mufflers are a better fit for me (Not as loud) and they are tucked in a lot better. More ground clearance..

Cuda, my Muzzy's don't have the inserts, nor holes to install them. Can you send a photo of yours?

I set the spring sag and mine is now rougher than I like. Would decrease pre-load but right now nothing drags in the twisties. Afraid softening it may make things drag when I'm playing in the Arkansas twisties with Cliff.

Currently building my own lowering links as I'm a bit too low..

Now at 1 1/4" drop. Changing that to 3/4" drop... >

If that works out, I'll soften the preload a bit.

NOTE: I don't like the adjustable links as I prefer to use my center stand..

Talked to Steve. {Geez he's knowledgeable!}

He thinks there's more power available with a bit of tuning.. :great:

Ride safe, Ted

PS: {Please don't tell him I sed something nice about him.}

https://www.revzilla.com/motorcycle/two-brothers-p1x-power-tip

I installed even a size smaller than the ones shown.

I installed even a size smaller than the ones shown.

Thanx Cuda. I missed that you had the Two Brothers.

Now I understand your first note...

Baffles are not available for the Muzzy's nor the Area P.

I went to the Area P as it is much quieter than the Muzzy's…

Ride safe, Ted

PS: Anyone looking for some nicequiet Muzzy's?

Now I understand your first note...

Baffles are not available for the Muzzy's nor the Area P.

I went to the Area P as it is much quieter than the Muzzy's…

Ride safe, Ted

PS: Anyone looking for some nice

Good looking set up.

Appear to be closer to the swing arm than mine. Nice!

Ride safe, Ted

Appear to be closer to the swing arm than mine. Nice!

Ride safe, Ted

Update on this old discussion;

I just returned from the COG National.

Still have the 2, Area P Mufflers and a 2006 ZX-1400 header.

I recently upgraded from Steve's Mountain Runner to his Mountain Runner Premium flash.

Runs great!

I LIKE IT!!!! :great: :great:

Ride safe, Ted

I just returned from the COG National.

Still have the 2, Area P Mufflers and a 2006 ZX-1400 header.

I recently upgraded from Steve's Mountain Runner to his Mountain Runner Premium flash.

Runs great!

I LIKE IT!!!! :great: :great:

Ride safe, Ted

Just returned from an Arkansas ride and couldn't be happier with this exhaust system.

But (being me) I have an idea I want to try and thought this old discussion might show ya'll that I'm crazy e'nuff to give it a try.

I want to install a valve that will allow me to "restrict" the exhaust system at low RPM's.

(I already have the valve)

But, I need an old aftermarket Mid pipe to do it..

Does anyone have an Area P or Delkevic Mid Pipe that they'll part with?

I don't care if it's damaged as I plan to cut it up and modify it.. <mad scientist grin>

See; https://forum.concours.org/index.php?threads/used-aftermarket-mid-pipe-wanted.53559/

Ride safe, Ted

PS: Since I did my build, Delkevic and Black Widow have developed Headers that would be a lot easier to install.

But (being me) I have an idea I want to try and thought this old discussion might show ya'll that I'm crazy e'nuff to give it a try.

I want to install a valve that will allow me to "restrict" the exhaust system at low RPM's.

(I already have the valve)

But, I need an old aftermarket Mid pipe to do it..

Does anyone have an Area P or Delkevic Mid Pipe that they'll part with?

I don't care if it's damaged as I plan to cut it up and modify it.. <mad scientist grin>

See; https://forum.concours.org/index.php?threads/used-aftermarket-mid-pipe-wanted.53559/

Ride safe, Ted

PS: Since I did my build, Delkevic and Black Widow have developed Headers that would be a lot easier to install.

Last edited:

My

Steve

My method will be better / easier / cheaper. Read up on my thread about getting the torque back for a delkevic header. Since you're running duals, I think you're going to need to reduce each output to maybe 1.375" . Trust me.Just returned from an Arkansas ride and couldn't be happier with this exhaust system.

But (being me) I have an idea I want to try and thought this old discussion might show ya'll that I'm crazy e'nuff to give it a try.

I want to install a valve that will allow me to "restrict" the exhaust system at low RPM's.

(I already have the valve)

But, I need an old aftermarket Mid pipe to do it..

Does anyone have an Area P or Delkevic Mid Pipe that they'll part with?

I don't care if it's damaged as I plan to cut it up and modify it.. <mad scientist grin>

See; https://forum.concours.org/index.php?threads/used-aftermarket-mid-pipe-wanted.53559/

Ride safe, Ted

PS: Since I did my build, Delkevic and Black Widow have developed Headers that would be a lot easier to install.

Steve

Aftermarket headers

Looking into replacing my stock manifold with an aftermarket header. Besides the ZX route we apparently have 3 direct fit choices that I know of, Area P, Delkevic and Black Widow. I would probably be using an Akrapovic slip-on as my muffler.. I've searched and seen opinions on Area p and...

I want a valve to... one that can bypass my muffler so when the straight pipe Harley guys come by I can turn up the volume.Just returned from an Arkansas ride and couldn't be happier with this exhaust system.

But (being me) I have an idea I want to try and thought this old discussion might show ya'll that I'm crazy e'nuff to give it a try.

I want to install a valve that will allow me to "restrict" the exhaust system at low RPM's.

(I already have the valve)

But, I need an old aftermarket Mid pipe to do it..

Does anyone have an Area P or Delkevic Mid Pipe that they'll part with?

I don't care if it's damaged as I plan to cut it up and modify it.. <mad scientist grin>

See; https://forum.concours.org/index.php?threads/used-aftermarket-mid-pipe-wanted.53559/

Ride safe, Ted

PS: Since I did my build, Delkevic and Black Widow have developed Headers that would be a lot easier to install.

See... I am always thinking of my riding brothers in the 2 wheel universe...

zrxmax; I just happen to know where you can get a dump valve.

You'll make less power, but it WILL be loud as hell!

The purpose of this looooooong discussion has been, discuss (exhaust) idea's/develop plans/and give them a try.

Early in this discussion I sed,,,,,,,,,,,

1* It's not how much power is made, it's where/how that power is made.

2* You'll never know if an idea works, if ya don't give it a try.

That sed. I'm now working on 2 different idea's......

1) Last night Steve called me and we discussed his exhaust restrictor design (See Post #220) for my 2 muffler system.

(Using his idea) I think I've now worked out a way to buy/build/install the "correct" sized restrictors in both of my Mid Pipes.

NOTE: In another discussion, Steve is helping me determine a restrictor size.

(Update) Restrictors have been ordered.

forum.concours.org

forum.concours.org

2) From early in this discussion, I've had the idea of a installing a variable valve in one of the Mid Pipes to restrict and control flow.

This is the valve I hope to try. (If I EVER find a used Mid pipe to cut up/modify) {Hint, Hint}

Ride safe, Ted

PS: If any of you (mad) tinkerers are interested in a different exhaust system for your bike, there has been a lot of idea's discussed here.

Some of them even worked!

You'll make less power, but it WILL be loud as hell!

The purpose of this looooooong discussion has been, discuss (exhaust) idea's/develop plans/and give them a try.

Early in this discussion I sed,,,,,,,,,,,

1* It's not how much power is made, it's where/how that power is made.

2* You'll never know if an idea works, if ya don't give it a try.

That sed. I'm now working on 2 different idea's......

1) Last night Steve called me and we discussed his exhaust restrictor design (See Post #220) for my 2 muffler system.

(Using his idea) I think I've now worked out a way to buy/build/install the "correct" sized restrictors in both of my Mid Pipes.

NOTE: In another discussion, Steve is helping me determine a restrictor size.

(Update) Restrictors have been ordered.

Do you have zx14 mufflers?

zx14, NOT 14r. If you have a zx14 muffler, can you please measure the exit diameter and post it up? thanks! Steve

2) From early in this discussion, I've had the idea of a installing a variable valve in one of the Mid Pipes to restrict and control flow.

This is the valve I hope to try. (If I EVER find a used Mid pipe to cut up/modify) {Hint, Hint}

Cutout Actuator 2" 51MM Exhaust OPEN Activated Style Vacuum Control Valve Pipes | eBay

Find many great new & used options and get the best deals for Cutout Actuator 2" 51MM Exhaust OPEN Activated Style Vacuum Control Valve Pipes at the best online prices at eBay! Free shipping for many products!

www.ebay.com

Ride safe, Ted

PS: If any of you (mad) tinkerers are interested in a different exhaust system for your bike, there has been a lot of idea's discussed here.

Some of them even worked!

Last edited:

Still tinkering with the Reducers in my {2 muffler) ZX-14 header system.

The first try didn't work as well as we hoped and I'm moving to another reducer version.

The problem seems to be that I have a 2 muffler/ZX-14 header, that is different than what Steve used. {his actually works}

Ride safe, Ted

The first try didn't work as well as we hoped and I'm moving to another reducer version.

The problem seems to be that I have a 2 muffler/ZX-14 header, that is different than what Steve used. {his actually works}

Ride safe, Ted

Update; I've learned some new info.

ZG-14 (Concours)

Entire head pipe dia is (1 3/8") {35 mm}

Exhaust port dia (x1) is (2 1/8") {54 mm}

Has Catalytic converter.

Cyl's 1/4 and 2/3 are paired.

ZX-14 2006 - 2007

Entire head pipe dia is (1 1/2") {38 mm}

Exhaust port dia (x2) is (2") {approx. 50 mm}

Has no Catalytic converter.

Cyl's 1/4 and 2/3 are paired.

ZX-14 2008 - 2011

Entire head pipe dia is (1 1/2") {38 mm}

Exhaust port dia (x2) is (2 1/8") {approx. 54 mm}

Has Catalytic converter.

Cyl's 1/4 and 2/3 are paired.

ZX-14R: (2013 to current)

Head pipe dia at the Flange is (1 1/2") {38 mm}

Head pipe dia from 5" below the Flange, flares to (1 11/16") {43 mm}

Exhaust port dia (x2) is (2 1/8") {54 mm}

No Catalytic converter.

Cyl's 1/2 and 3/4 are paired.

Full Area P System

Head pipe dia at the Flange is (1 1/2") {38 mm}

Head pipe dia from 2" below the Flange, flares to {approx. 1 23/32"}) {44 mm}

Exhaust port dia (x1) is approx. (2 1/4") {57 mm}

No Catalytic converter.

Cyl's 1/2 and 3/4 are paired.

Yoshimira System

Head pipe dia at the Flange is (1.475") {37 mm}

Head pipe dia from 2" below the Flange, flares to {1.66" od}) {42 mm}

Exhaust port dia (x1) is approx. (2") {51 mm}

No Catalytic converter.

Cyl's 1/2 and 3/4 are paired.

Ride safe, Ted

(As always; If someone see's an error in my info, please let me know)

ZG-14 (Concours)

Entire head pipe dia is (1 3/8") {35 mm}

Exhaust port dia (x1) is (2 1/8") {54 mm}

Has Catalytic converter.

Cyl's 1/4 and 2/3 are paired.

ZX-14 2006 - 2007

Entire head pipe dia is (1 1/2") {38 mm}

Exhaust port dia (x2) is (2") {approx. 50 mm}

Has no Catalytic converter.

Cyl's 1/4 and 2/3 are paired.

ZX-14 2008 - 2011

Entire head pipe dia is (1 1/2") {38 mm}

Exhaust port dia (x2) is (2 1/8") {approx. 54 mm}

Has Catalytic converter.

Cyl's 1/4 and 2/3 are paired.

ZX-14R: (2013 to current)

Head pipe dia at the Flange is (1 1/2") {38 mm}

Head pipe dia from 5" below the Flange, flares to (1 11/16") {43 mm}

Exhaust port dia (x2) is (2 1/8") {54 mm}

No Catalytic converter.

Cyl's 1/2 and 3/4 are paired.

Full Area P System

Head pipe dia at the Flange is (1 1/2") {38 mm}

Head pipe dia from 2" below the Flange, flares to {approx. 1 23/32"}) {44 mm}

Exhaust port dia (x1) is approx. (2 1/4") {57 mm}

No Catalytic converter.

Cyl's 1/2 and 3/4 are paired.

Yoshimira System

Head pipe dia at the Flange is (1.475") {37 mm}

Head pipe dia from 2" below the Flange, flares to {1.66" od}) {42 mm}

Exhaust port dia (x1) is approx. (2") {51 mm}

No Catalytic converter.

Cyl's 1/2 and 3/4 are paired.

Ride safe, Ted

(As always; If someone see's an error in my info, please let me know)

Last edited:

I already bought (I think) a 2012 ZX-14R Header and took the measurements.Ted Here is the 2020 ZX14R header, I have read on a few places 2017 went to a three way cat , header collector and each muffler I’m going to grab this header and let you know what I find

The 2012 does not have a cat, and I think are same head pipe dimensions as the one you're looking at.

When I did the ZX-14 header install I bought both headers. (2006 ZX 14 and 2012 ZX-14R)

I opted for the ZX-14 because of smaller head pipe size and cylinder pairing.

Last edited:

Update; I've learned some new info.

ZG-14 (Concours)

Entire head pipe dia. is (1 3/8") {35 mm}

** Head pipe Dia. does not flare.

Exhaust port dia. (x1) is (2 1/8") {54 mm}

Has Catalytic converter.

Cyl's 1/4 and 2/3 are paired.

Early ZX-14 System 2006 - 2007

Entire head pipe dia. is (1 1/2") {38 mm}

** Head pipe Dia. does not flare.

Exhaust port dia. (x2) is (2") {approx. 50 mm}

Has no Catalytic converter.

Cyl's 1/4 and 2/3 are paired.

Later ZX-14 System 2008 - 2011

Entire head pipe dia. is (1 1/2") {38 mm}

** Head pipe Dia. does not flare.

Exhaust port dia. (x2) is (2 1/8") {approx. 54 mm}

Has Catalytic converter.

Cyl's 1/4 and 2/3 are paired.

ZX-14R system: (2013 to current)

Head pipe dia. at the Flange is (1 1/2") {38 mm} and then increases in Dia.

** Approx. 5" from the head, the Head pipe dia. increases from (1 1/2") {38 mm} to (1 11/16") {43 mm}

Exhaust port dia. (x2) is (2 1/8") {54 mm}

No Catalytic converter.

Cyl's 1/2 and 3/4 are paired.

Full Area P System

Head pipe dia. at the Flange is (1 1/2") {38 mm} and then increases in Dia.

** Approx. 2" from the head, the Head pipe dia. increases from (1 1/2") {38 mm} to {approx. 1 23/32"}) {44 mm}

Exhaust port dia. (x1) is approx. (2 1/4") {57 mm}

No Catalytic converter.

Cyl's 1/2 and 3/4 are paired.

Yoshimira System

Head pipe dia. at the Flange is (1.475") {37 mm} and then increases in Dia.

** Approx. 2" from the head, the Head pipe dia. increases from (1.475") {33 mm} to (1.66") {42 mm}

Exhaust port dia. (x1) is approx. (2") {51 mm}

No Catalytic converter.

Cyl's 1/2 and 3/4 are paired.

Hindle System **

Head pipe dia. at the Flange is (1 1/2") {38 mm} and then increases in Dia.

**Approx. 6" from the head, the Head pipe dia. increases from (1 1/2") {38 mm} to (1 23/32") {44 mm}.

Exhaust port dia. (x1) is approx. (2 1/4") {57 mm}

No Catalytic converter.

Cyl's 1/2 and 3/4 are paired.

Ride safe, Ted

(As always; If someone see's an error in my info, please let me know)

ZG-14 (Concours)

Entire head pipe dia. is (1 3/8") {35 mm}

** Head pipe Dia. does not flare.

Exhaust port dia. (x1) is (2 1/8") {54 mm}

Has Catalytic converter.

Cyl's 1/4 and 2/3 are paired.

Early ZX-14 System 2006 - 2007

Entire head pipe dia. is (1 1/2") {38 mm}

** Head pipe Dia. does not flare.

Exhaust port dia. (x2) is (2") {approx. 50 mm}

Has no Catalytic converter.

Cyl's 1/4 and 2/3 are paired.

Later ZX-14 System 2008 - 2011

Entire head pipe dia. is (1 1/2") {38 mm}

** Head pipe Dia. does not flare.

Exhaust port dia. (x2) is (2 1/8") {approx. 54 mm}

Has Catalytic converter.

Cyl's 1/4 and 2/3 are paired.

ZX-14R system: (2013 to current)

Head pipe dia. at the Flange is (1 1/2") {38 mm} and then increases in Dia.

** Approx. 5" from the head, the Head pipe dia. increases from (1 1/2") {38 mm} to (1 11/16") {43 mm}

Exhaust port dia. (x2) is (2 1/8") {54 mm}

No Catalytic converter.

Cyl's 1/2 and 3/4 are paired.

Full Area P System

Head pipe dia. at the Flange is (1 1/2") {38 mm} and then increases in Dia.

** Approx. 2" from the head, the Head pipe dia. increases from (1 1/2") {38 mm} to {approx. 1 23/32"}) {44 mm}

Exhaust port dia. (x1) is approx. (2 1/4") {57 mm}

No Catalytic converter.

Cyl's 1/2 and 3/4 are paired.

Yoshimira System

Head pipe dia. at the Flange is (1.475") {37 mm} and then increases in Dia.

** Approx. 2" from the head, the Head pipe dia. increases from (1.475") {33 mm} to (1.66") {42 mm}

Exhaust port dia. (x1) is approx. (2") {51 mm}

No Catalytic converter.

Cyl's 1/2 and 3/4 are paired.

Hindle System **

Head pipe dia. at the Flange is (1 1/2") {38 mm} and then increases in Dia.

**Approx. 6" from the head, the Head pipe dia. increases from (1 1/2") {38 mm} to (1 23/32") {44 mm}.

Exhaust port dia. (x1) is approx. (2 1/4") {57 mm}

No Catalytic converter.

Cyl's 1/2 and 3/4 are paired.

Ride safe, Ted

(As always; If someone see's an error in my info, please let me know)

Last edited: